MOCVD

Metal-Organic Chemical Vapor Deposition (MOCVD) is a deposition technique in which a chemical reaction occurs at the heated surface of the substrate, leading to the deposition of the desired material. The elements to be deposited are therefore not introduced in atomic form such as in metal evaporation or MBE (refered to as physical vapor deposition techniques). In Chemical Vapor Deposition (CVD) the reactants are introduced in the form of reactant gases or "precursors". For example, zinc oxide may be deposited by reaction of the two precursors diethyl zinc and ethanol. The precursors are carried to the reaction chamber by a carrier gas such as nitrogen or helium. The precursors do not mix until they reach the chamber. By controlling the temperature of the substrate we can cause the chemical reaction between the precursors to occur at the surface of the substrate but no sooner. The technique allows for relatively fast depostion that is controlled by adjusting the numerous deposition parameter such as precursor partial pressure, gas flow, substrate temperature, chamber temperature, reactor back pressure, etc...

ZnO

The first films we have grown in our MOCVD chamber are ZnO films on Si substrates. Diethyl zinc ((C2H5)2Zn) and ethanol (CH3CH2OH) were used as precursors, and He as the carrier gas for both. The DEZ was maintained at 25 °C in a heated circulating bath, and ethanol at 55 °C. The flow rate through each bubbler was 4 sccm, and the growth time was 30 minutes. We grew films at several substrate temperatures, ranging from 100-300 degrees C, and are still working on optimizing growth parameters. Film growth and crystal quality will be studied by XPS, XRD, XAS, and SEM.

TiO2

Growth recipe:

Precursor: Titanium isopropoxide (Ti[OCH(CH3)2]4)

Carrier Gas: N2 or He

Oxidant: > 99.5% pure O2

SnO2

Growth recipe:

Precursor: Tetraethyltin (Sn(C2H5)4)

Carrier Gas: N2 or He

Oxidant: > 99.5% pure O2

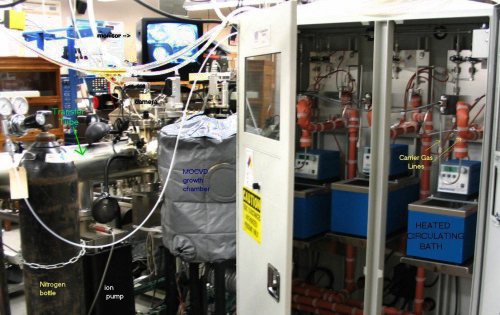

Gas lines, bubblers and heat baths

Our system is capable of growing films at very low pressures, ~10-9 Torr. For convenience, we have a load-lock chamber at the end of our transfer tube. This allows us to quickly introduce and exchange growth substrates from our MOCVD chamber without venting the entire system. The transfer tube allows us to carry samples from the MOCVD chamber to the analysis chamber under vacuum. Once the substrate is placed in the load-lock chamber and an acceptable pressure has been achieved, the sample can be moved down the transfer tube via a cart until it joins with a manipulator arm that allows us to transfer the sample from the transport cart to the growth chambers. Gate valves between the load-lock chamber and the transfer tube, and the transfer tube and the MOCVD chamber allow us to isolate various parts of the system and cameras mounted in critical locations along the transfer tube assist in sample manipulation and transfer.

Growth chamber (center), transfer tube (left), gas cabinets (right)

Diagram of bubbler operation.